February 2023

ESG Report

Photos Courtesy of Continew

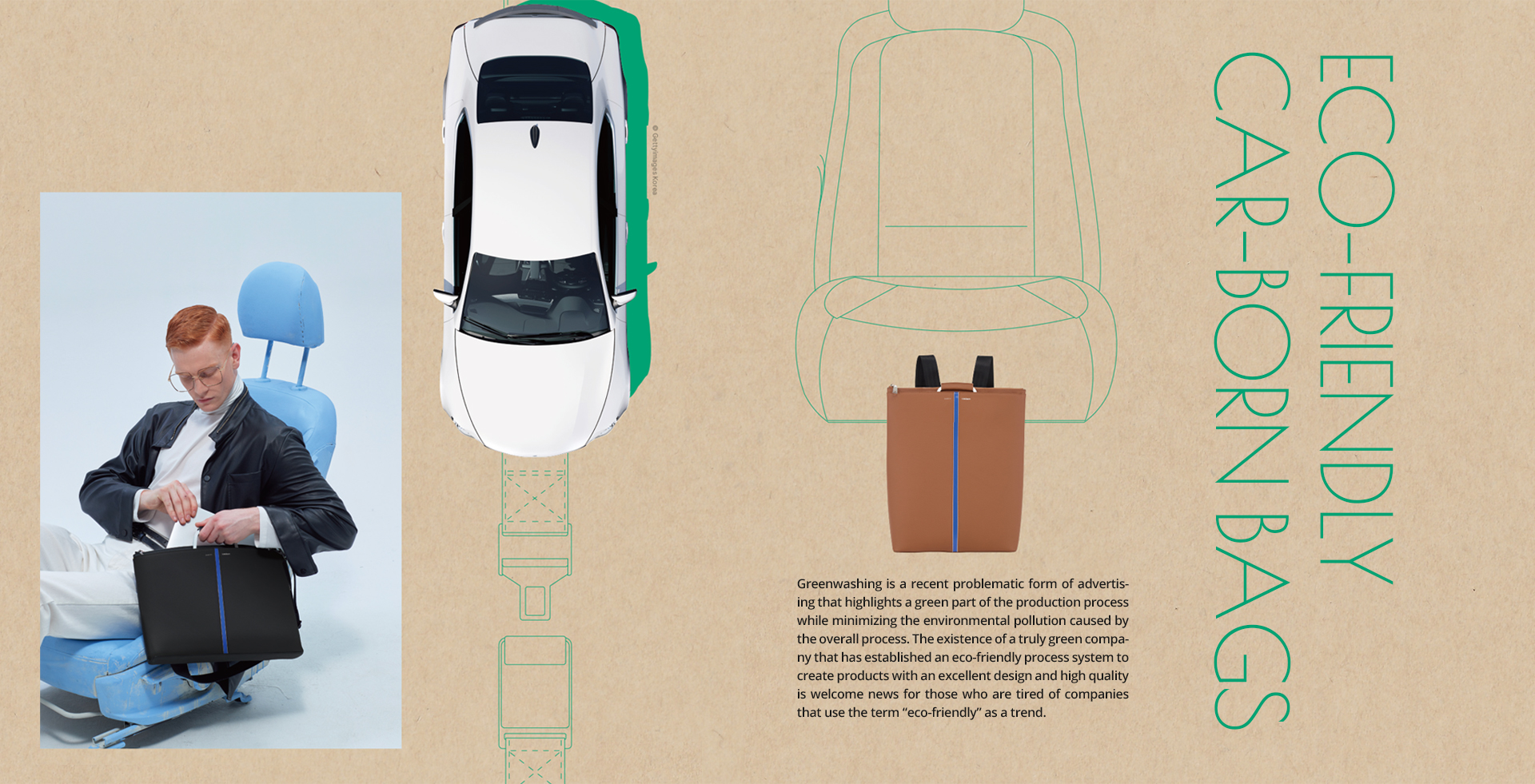

A bag with the emblem of a luxury sports car has recently become a hot topic in Korea. The design and pattern of the bag are reminiscent of a car seat, which is intriguing as the bag is actually made from natural leather that came from what it resembles.

A Luxury Car Becomes a Bag

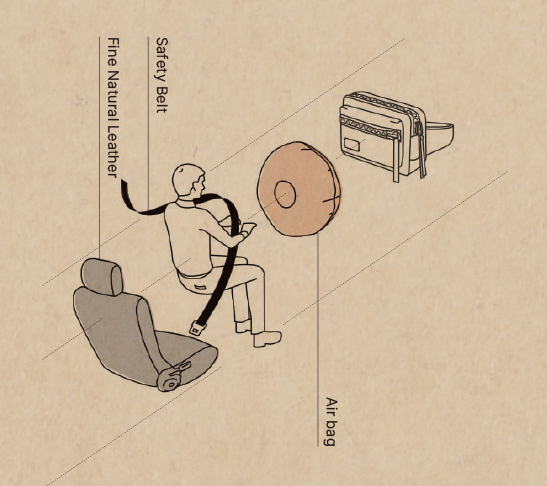

A car is a collection of many different kinds of materials such as metal, leather, plastic and nylon. Cars that have lost their original function are dismantled, and most of the materials are discarded. Continew is a company that refines usable materials such as leather seats, airbags and seat belts to turn them into something new.

Continew’s Luxury Line, a line that includes bags that are made from upcycled leather from luxury cars such as Bentley, Porsche and Ferrari, has been drawing daily attention in Korea. A spokesperson for Continew said, “The seats in luxury cars are made from the finest fabric. There has been a certain prejudice that upcycled products are clunky in design and low in quality. We want to break that prejudice by using leather that comes from the seat of a luxury car.”

As expected, the sold-out Luxury Line has become a symbolic piece that was able to overcome the aforementioned prejudice against upcycled products thanks to the excellent quality, sophisticated design and rather expensive price.

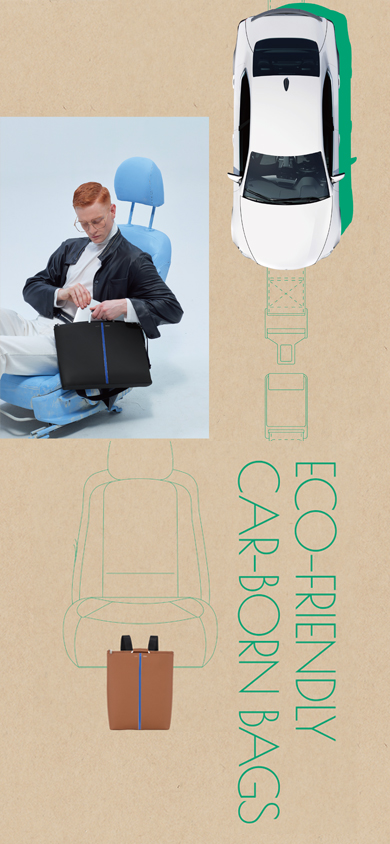

Continew uses safety belts, high-quality natural leather and airbags sourced from discarded cars.

Continew uses safety belts, high-quality natural leather and airbags sourced from discarded cars. A bag made from airbags, the Continew Road Trip Air Big Tote

A bag made from airbags, the Continew Road Trip Air Big Tote Various bags that are made from airbags obtained from end-of-life vehicles

Various bags that are made from airbags obtained from end-of-life vehiclesEco-friendly Process System

What is the process like in which parts from scrap cars are upcycled into new products? A bag, for example, goes through the following seven-step process: collection, cutting, steaming, washing, drying, sorting and manufacturing.

What is noteworthy here is Continew’s efforts to follow an eco-friendly upcycling manufacturing process. “You can’t call yourself ‘eco-friendly’ just by using upcycled or recycled materials. The entire manufacturing process should also be eco-friendly. If making an upcycled product consumes more energy or emits more carbon dioxide than making a regular product, then it’s not truly green.”

Continew Zero to One was formed based on the philosophy behind creating an ecological factory. Continew Zero to One has developed a green process through the self-replenishment of electrical energy from solar power and a hybrid water regeneration system. The factory uses filtered rainwater for washing.

The wastewater is then filtered again and used as washing water. The electrical energy required to operate the machines (such as the washers) is obtained through solar energy. Continew has also developed its own eco-friendly detergent (with coconut oil and baking soda as the main ingredients) that is used for washing products.

More than 90% of the offline store space (created to give customers a place to actually see the products) is made of reusable resources. The floors are made from wood that came from the classrooms of an abandoned school while old tires have been used to create the design. The walls are decorated with discarded bricks, and the shelves are made of sawdust. Even the store’s chandelier is made from plastic waste.

It wasn’t an easy process. According to officials, Continew invested 18 months in research and construction to create an ecological factory. Amid the prevalent greenwashing, Continew’s philosophy and attitude make people think more about the true meaning of the word “eco-friendly.”

The exterior of the water recycling facility of Continew Zero to One

The exterior of the water recycling facility of Continew Zero to OneA Virtuous Cycle of Resources

Continew has recently introduced a variety of upcycled products from bags, wallets and shoes to accessories such as car key cases, key rings, bag charms and cell phone pouches. Continew is working towards diversifying its product line in the future. The company is accelerating its product development by using different scrap parts from cars. For example, the company is currently developing a boombox made from speakers that come from old cars.

Continew is expanding its range of upcycled materials to go beyond scrapped cars. “We are trying to expand our collaborations with companies that use discarded materials. It would be great if we could expand our scope of business by developing products made from various materials while helping companies eliminate the need for waste. It’s a win-win situation. We already have some projects in progress, so I think we’ll be able to show off the results soon.”

Ultimately, Continew wants to create a virtuous cycle of resources. The company aims to establish an upcycling environment in the fashion industry through a virtuous cycle of resources. Upcycling is the only way to use limited resources for as long as possible, which is why expectations are high for the future of Continew.

View of all

View of all